Machinery Health Monitoring and Fault Diagnostics - adding Motor Analysis to a Vibration Program

Motor current and magnetic flux measurements are very important parameters to determine motor health. Motor current signature analysis program detects motor broken/ cracked bars as well as problem with the high resistance joints on any Induction motors. Flux analysis is used to detect stator related shorts, broken rotor bars and changes in voltage balance. Motor current and flux analysis technology, with embedded analysis expertise, helps complete a total Machinery Health Management program by diagnosing electrical problems that may be missed with a vibration monitoring program.

Detecting Broken Rotor Bars

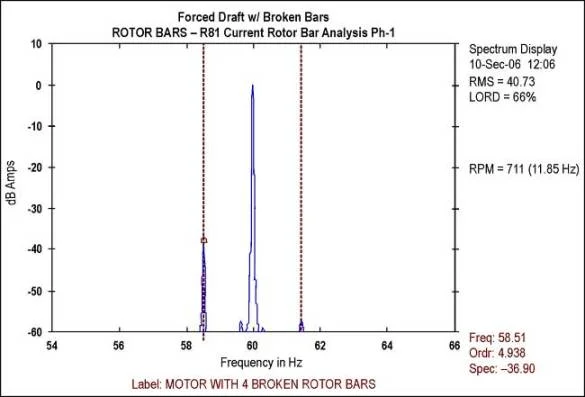

Heat and fatigue, especially with excessive motor starts or overloading, can lead to broken rotor bars in electric motors. Broken rotor bars eventually lead to motor failure, and can cause secondary damage to stator windings. Rotor bar damage can be difficult to detect in a vibration signature. Therefore motor current analysis is a valuable additional technology to apply as part of a complete Machinery Health Management program. Motor current analysis provides a conclusive indication of broken rotor bars by identifying the "slip times number of poles" sidebands around line frequency (50 Hz), and comparing the sideband amplitude to the amplitude of the line frequency peak. If the sideband amplitude rises to within 45 dB of the line frequency peak, a problem is indicated, 35 dB indicates severe damage. In the plot below, the 60 Hz line frequency peak is shown in the center. The software has calculated and drawn dotted lines to identify the sideband peaks. Notice that the amplitude of the peak on the left is within 36.9 dB of line frequency amplitude. This indicates significant rotor bar damage.

Motor current analysis usually requires opening up Motor Control Cabinets in order to access electrical wiring with a current clamp. This can be dangerous, and requires an Electrician to be involved, and may even require suiting up in special gear. To avoid the risk and inconvenience of opening up MCC's, the flux coil can be used. The flux coil allows you to trend motor electrical condition using magnetic flux measurements taken directly off the end bell of the motor.

The flux measurement shows the same information as the current measurement, though the amplitudes depend on where the flux coil is placed in the magnetic field. Therefore, the flux data is used to look for changes in the trend on a monthly basis. When amplitudes start to rise, a current clamp is then used to confirm the absolute severity. In addition to the convenience flux analysis provides, it also provides additional diagnostic information not found in the current signature. In addition to rotor bar condition, flux analysis gives indications of changes in stator winding condition.

Adding Motor Analysis to a Vibration Program

If you already have a Vibration monitoring program in place, it is easy to add motor analysis by simply adding the required software and flux and current coil. It is possible to have the database wizard, which can will automatically configure the measurement points for proper analysis, and the Expert System can automatically screen through large amounts of data, analyze, and report on motor condition, so you don't have to be an expert at reading the plots.

- Kaushal Shrivastava